Since November 2018, the world’s highest, most advanced 3S cableway carries passengers to the Matterhorn Glacier Paradise. The lift combines cutting-edge technology with top-class design. This enhances ride comfort, makes the cableway more stable, minimizes essential maintenance work and increases the service life of the individual components – an outstanding technical achievement. From 1 July 2023, the identical 3S cableway Matterhorn Glacier Ride II will connect the Matterhorn Glacier Paradise mountain station with the Testa Griggia valley station on the border with Italy. Cableway manufacturer LEITNER is the contractor with overall responsibility for the construction of both of the 3S cableways.

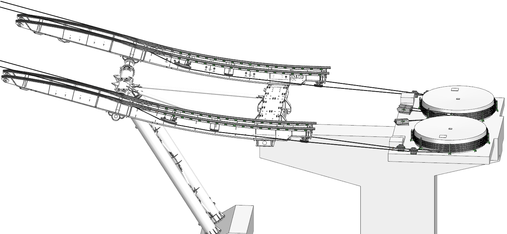

The Matterhorn Glacier Ride I 3S cableway carries 25 cabins, with the help of three cables for each cabin. It conveys them over three support towers between the valley station at Trockener Steg and the mountain station. The Matterhorn Glacier Ride II will transport ten cabins between the Testa Griggia valley station and the Matterhorn Glacier Paradise mountain station from 1 July 2023, without additional supports between the stations. Two of the cables, which act as stabilizing support cables, are suspended between the stations in both directions of travel. The hauling cable is in the form of a continuous loop made by splicing the ends together. It circulates between the two stations and transports the 25 cabins, which are attached to the cables with clips. On arrival at the stations, the cabins are uncoupled from the hauling cable and drawn slowly through the terminals on tyre conveyors. They are reattached to the hauling cable before they leave again.

More stable, more comfortable and more efficient

3S cableways combine the most advanced technology with the highest safety standards and greatest ride comfort. They offer numerous advantages over conventional circulating cableways, ensuring a more stable ride in high winds and providing increased carrying capacity and greater driving speed. With a maximum speed of 7.5 metres per second, the Matterhorn Glacier Ride I can carry up to 2000 passengers an hour to the Matterhorn Glacier Paradise. The carrying capacity of the Matterhorn Glacier Ride II will be around 1,300 people per hour.

Different ropes for different jobs

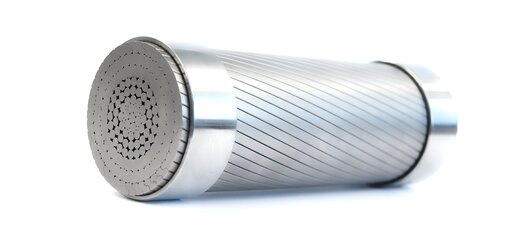

The hauling cable and support cables of the 3S cableways were all made by the Swiss company FATZER. The support cables have a smooth surface, allowing the cabins to glide quietly along them. This type of cable is known as a fully locked spiral strand rope. The outer layer is formed by wires with a shaped profile which can interlock like a zip fastener.

This manufacturing technique also means the outer wires cannot escape from the rope bundle in the event of breakage. Its smooth surface also helps protect the hauling cable, preventing the penetration of moisture and dirt. Two of the four hauling cables are fitted with fibre-optic cables, guaranteeing a redundant data link between the stations. These links also ensure continuous monitoring of key data, for example the integrity of the multi-strand cable anchors at the mountain station and cable tension, as well as Internet and Intranet connections.

By contrast, the hauling cable consists of twisted strands, spliced to form a continuous loop. It comprises six strands, each of which is made from 36 individual wires. Unlike the support cable, its surface is not flat, but wound around a core strand in a spiral-linear pattern. This process makes the hauling cable particularly dynamic and also highly resilient under mechanical strain.

Read more about the manufacturing of the ropes here: Manufacturing the rope - a science in itself

Modern cabins, each with 28 seats

The cabins, made by the specialist manufacturer SIGMA, measure 3.7 by 3.6 by 2.2 (height) metres and have 28 seats per cabin, larger than any other continuous circulating cableway. The wide entry is at ground level, making it easy to carry on sports gear and providing a barrier-free entrance and exit for wheelchairs and pushchairs or prams.The spacious cabins offer a spectacular view of the high-alpine mountain landscape through all-round panorama windows. The lighting concept was created in cooperation with Bartenbach Lighting Design. State-of-the-art technology is also a feature of the comprehensive energy supply concept, which comprises supercapacitators at the two stations, a roller generator in the running gear, and solar panels. The cabins for the Matterhorn Glacier Ride I & II were designed by the world-famous PININFARINA studio and feature heated seats inspired by car design and the use of high-quality materials such as leather and Alcantara.

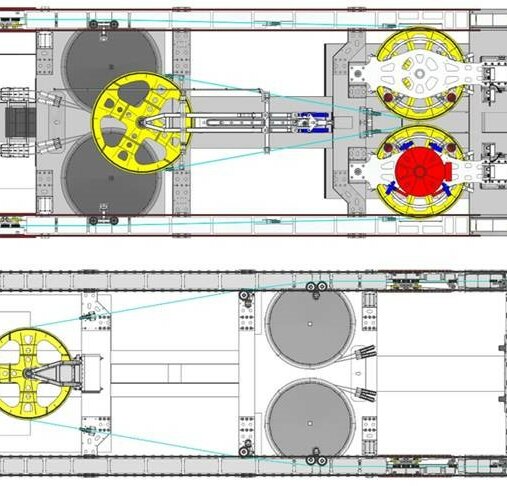

Powered by Leitner DirectDrive

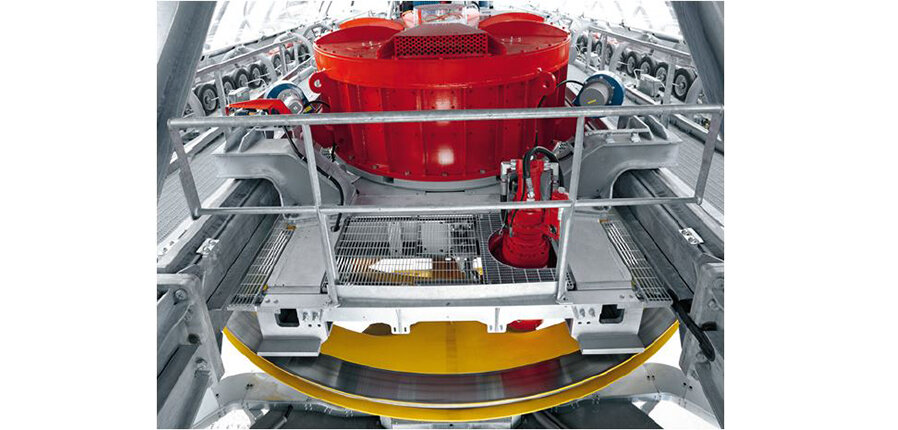

The drive mechanism of the 3S cableways is also special: the LEITNER DirectDrive system is a unique cableway drive mechanism without a gearbox. In a conventional drive system, the gears transmit the motion generated by the motor to power the cableway.

The LEITNER DirectDrive system comprises a low-speed synchronous motor, the output shaft of which is connected directly to the cable sheave. The drive mechanism has few components and works at low speed, significantly reducing wear and tear and the risk of the cableway breaking down. In addition to increased reliability, the drive also operates at much lower noise levels. Gear oil, essential in conventional transmissions, can be dispensed with entirely in the DirectDrive, which means it is particularly eco-friendly.

The Matterhorn Glacier Ride I has two drive mechanisms, both mounted on a cable sheave. What make this system special is that each one is easily powerful enough to drive the cableway on its own if the other one fails. The braking system comprises a service brake and a safety brake, both of which act directly on the drive sheave and are equipped with their own independent hydraulic systems. That makes the mechanism especially safe.

The control system – centrepiece of the cable way

Thanks to the LeitControl system made by LEITNER, operation of the installation is simple and transparent. A single control panel handles all the functions required for routine, day-to-day operations. Whereas conventional control systems used to require up to seven substeps to complete some individual operations, the LeitControl has the whole procedure stored as a single operation, which will run fully automatically without further intervention. The control system enables continuous monitoring of the cableway operations via computer screen and on a mobile device.